Rift and Quartered hardwood flooring products is one of our specialties. We have great pricing and availability on any standard or custom floor you may need. Available cuts are rift and quartered, quarter sawn only and rift sawn only. Each of these cuts will give a unique look to your floor. These type of cuts will also be more dimensionally stable to help resist expansion and contraction while also increasing the overall surface hardness. When approved, rift and quartered is the preferred type of hardwood floor when installing over a radiant heating system. We offer these cuts in all possible species with White Oak and Red Oak being the most popular. Long lengths, wide widths, solid or engineered, we have it all.

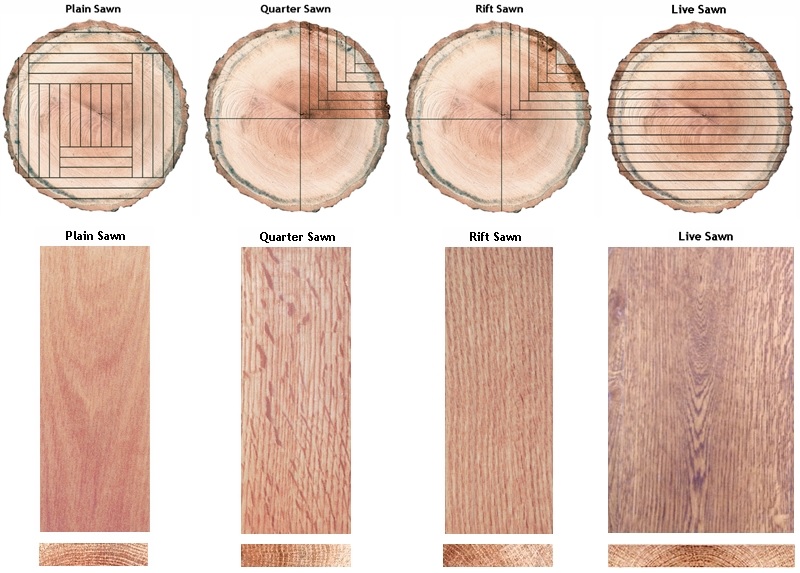

Below you will find descriptions of the different characteristics of rift and quartered cuts. Above you can see what parts of the log each cut comes from and how this changes the look of the grain patterns.

Quartered Only/Quarter Sawn – 50% of each board must these quartered characteristics: In cross section the angle of the annual ring must be tangent to the face of each board and be between 45 to 90. Grain needs to be mostly parallel to the length of boards. Medullary ray fleck observed and wider than 1/16”.

Rift Only/Rift Sawn – 75% of each board must contain these rift characteristics: In cross section the angle of the annual ring must be tangent to the face of each board and be between 30 to 60. Grain needs to be mostly parallel to the length of boards. Medullary ray fleck, when observed, less than 1/16”.

Rift and Quartered – this cut will be a mix of rift sawn and quarter sawn that is developed from the production run. This will be the most common and affordable option of these cuts.

Live Sawn – live sawn (also called French Cut), develops boards that can have all of the characteristics of each cut in the same piece of flooring. This is the sawing method of flooring in the popular, European French Oak.

Plain Sawn – this will be the most common and affordable of all the cuts. Plain sawn produces a wide/spread out grain appearance commonly known as “Cathedral” grain.